LPG (liquefied petroleum gas) is used in industrial, commercial, agricultural, and manufacturing applications,LPG is a mix of propane (C3H8) and Butane (C4H10).

LPG Bobtails are used for LPG distribution for local delivery , capacity ranging between 5-30 m3

Bobtails are assembled on chassis MAN, DAF, Volvo, Mercedes etc. on axles 4×2 (4×4) and 6×2 (6×4, 6×6)

The GVW (Gross Vehicle Weight) of the selected truck should be suitable for total load ( gas weight+tank weight)

During the selection the capacity and diameter for tank, the chassis length (CE : Cab to End ) should be taken into account

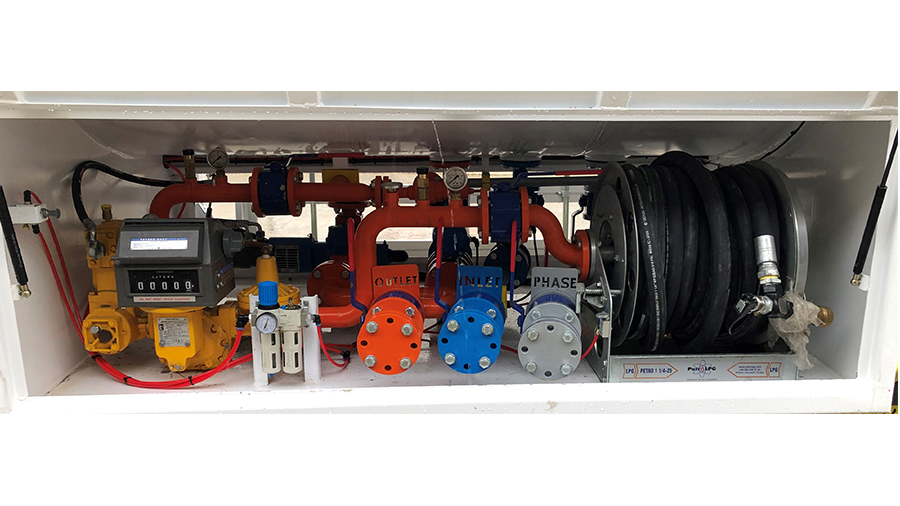

This system provided with Unloading ,Transferring and Metering system and all needed safety relief valves

The welding tests that can be done for tank: UT (Ultrasonic Test ) and RT ( RadiographicTest ) for joints, BT Test will be done for welded flanges

The hydrostatic test will be done by water pressure according to code by THIRD PARTY

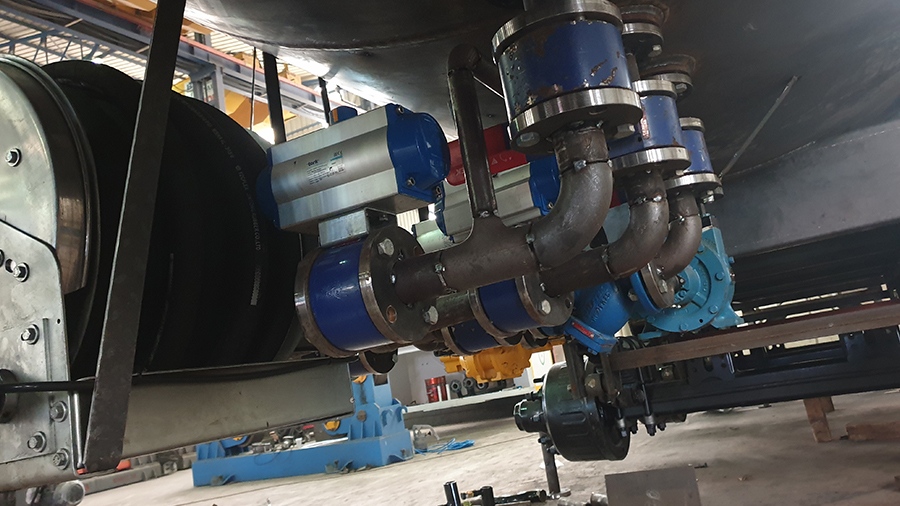

This system has three options for connecting pump to truck

1. LPG pump with hydrolic motor connected to truck's PTO

2. LPG pump with the direct coupling (shaft) to truck's PTO

3. LPG pump with electric motor

| DESIGN PARAMETERS FOR BOBTAIL TANK (PRESSURE VESSEL) | |

|---|---|

| Design Code | AD 2000 MERKBALTTER, EN 12493 ,EN 13445 ,ASME CODE and other codes |

| Capacity | ( 5 - 30 m3 ) |

| Body Type | Horizontal, Cylindrical |

| Heads Type | Elliptical or Hemispherical , Heat treatment 600 C º |

| Material | SA 516 Gr 70 / EN-10028.3 ( P355NH-P355NL1) / EN-10028.2 ( P355GH-P265GH) |

| Design Temperature | (-20 C° / +70 C°) |

| Design Pressure | 17,1 - 18 BAR |

| Test Pressure | 26,25 - 27.5 BAR |

| Welding | SAW -Submerged Arc Welding |

| Piping | SCH 40, SCH80 seamless pipes |

| Tests | UT (Ultrasonic Test ) - X-Ray : RT ( RadiographicTest ) - BT ( Beta Test ), Hydrostatic Test |

| Paint | Sandblasting will be done firstly, 2 layers of epoxy base paint, then 2 layers of paint . |

| LIST OF ACCESSORIES CAN BE USED FOR BOBTAIL TANK | |

|---|---|

| Fow meter (size : 2 ‘’, 2.5 ‘’ , 3 ") mechanical or electronic , metering by LT or KG | |

| LPG pump ( with hydraulic motor to truck's PTO or direct couling (shaft) to truck's PTO or pump with electric motor ) | |

| Hose reel and 25 m hose provided with 1 ¼ ʺ filling head - air motor for pulling back hose will provided | |

| 2 ʺ , 1 ¼ ʺ , 1/2 ʺ Pressure Relief Valve for tank and piping | |

| DN50 - 2 ʺ Pneumatic Actuator Valve | |

| 2” Hydraulic Excess Flow Valve | |

| 1 LT Hydraulic operator | |

| Magnetic or Mechanical Level Indicator | |

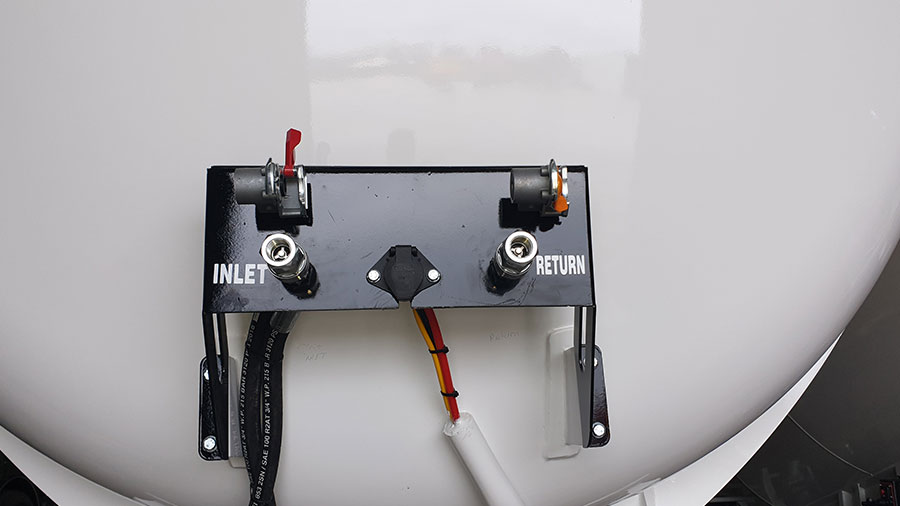

| 1 ¼ ʺ Double Check Filler Valves- Filling Head | |

| 1 ʺ Bypass | |

| Manometer (0 - 40 bar) | |

| Thermometer (-20 / +70 C˚ ) | |

| DN50 PN40 - 2 ʺ Monoblock Ball Valve | |

| DN50 PN40 - 2 ʺ Strainer Valve | |

| 3 ¼ ʺ - 2 ʺ Acme Cap + Nipple | |

| 2 ¼ ʺ - 1 ¼ ʺ Acme Cap + Nipple |