Download catalogue

Download catalogue

LPG BOBTAIL TANKS

- LPG (liquefied petroleum gas) is used in industrial, commercial, agricultural, and manufacturing applications, LPG is a mix of propane (C3H8) and Butane (C4H10).

- LPG Bobtails are used for LPG distribution for local delivery, capacity ranging between 5-30 m3

- Bobtails are assembled on chassis MAN, DAF, Volvo, Mercedes etc. on axles 4×2 (4×4) and 6×2 (6×4, 6×6)

- The GVW (Gross Vehicle Weight) of the selected truck should be suitable for total load ( gas weight+tank weight)

- During the selection the capacity and diameter for tank, the chassis length (CE : Cab to End ) should be taken into account

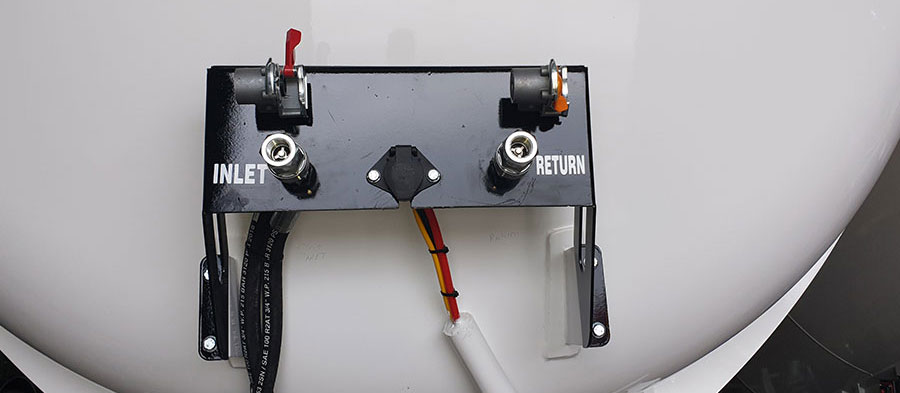

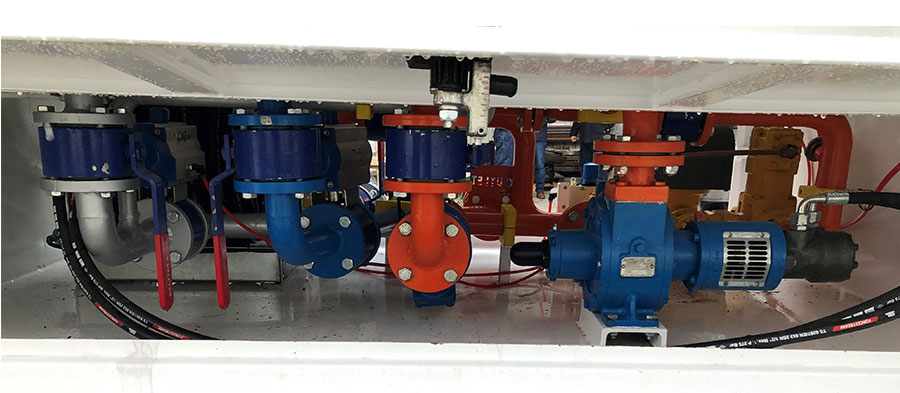

- This system provided with Unloading ,Transferring and Metering system and all needed safety relief valves

- The welding tests that can be done for tank: UT (Ultrasonic Test ) and RT ( RadiographicTest ) for joints, BT Test will be done for welded flanges

- The hydrostatic test will be done by water pressure according to code by THIRD PARTY

- 1. LPG pump with hydrolic motor connected to truck's PTO

- 2. LPG pump with the direct coupling (shaft) to truck's PTO

- 3. LPG pump with electric motor

This system has three options for connecting pump to truck:

TECHNICAL SPECIFICATIONS

Download catalogue| DESIGN PARAMETERS FOR BOBTAIL TANK (PRESSURE VESSEL) | |

|---|---|

| Design Code | AD 2000 MERKBALTTER, EN 12493 ,EN 13445 ,ASME CODE and other codes |

| Capacity | ( 5 - 30 m3 ) |

| Body Type | Horizontal, Cylindrical |

| Heads Type | Elliptical or Hemispherical , Heat treatment 600 C º |

| Material | SA 516 Gr 70 / EN-10028.3 ( P355NH-P355NL1) / EN-10028.2 ( P355GH-P265GH) |

| Design Temperature | (-20 C° / +70 C°) |

| Design Pressure | 17,1 - 18 BAR |

| Test Pressure | 26,25 - 27.5 BAR |

| Welding | SAW -Submerged Arc Welding |

| Piping | SCH 40, SCH80 seamless pipes |

| Tests | UT (Ultrasonic Test ) - X-Ray : RT ( RadiographicTest ) - BT ( Beta Test ), Hydrostatic Test |

| Paint | Sandblasting will be done firstly, 2 layers of epoxy base paint, then 2 layers of paint . |