Download catalogue

Download catalogue

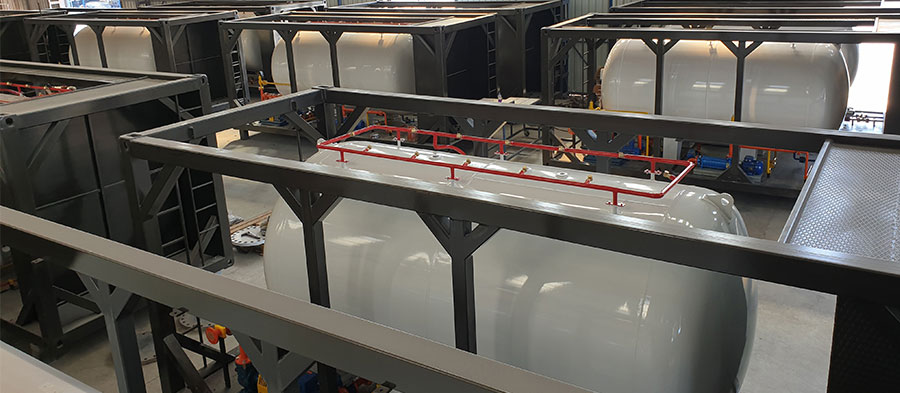

LPG SKID SYSTEM

- LPG (liquefied petroleum gas) is used in industrial, commercial, agricultural, and manufacturing applications.

- LPG is a mix of propane (C3H8) and Butane (C4H10)

- LPG Skid Station (Autogas Filling Sation), it is mobile station builted on steel chasssis used for filling car or gas cylinders

- Dispenser single or double nozzle can be used for filling car or gas cylinder, the dispenser can mesuaring by (LT) or (kg - mass flow)

- The scales used for filling gas cylinder, the scales can be mechanical or electronic (digital)

- The welding tests that can be done : UT (Ultrasonic Test ) and RT (RadiographicTest) for joints, BT Test will be done for welded flanges

- The hydrostatic test will be done by water pressure according to code by THIRD PARTY

Simple Skid:

- This kind of skids provided with tank gauging system

- In this case the skid will be automated by adding automation devices : gauging probe, software connected to PC ...etc

- This software connected to this system can show all needed reports for user , like daily report , shift report, density ,gas level in the tank ... etc

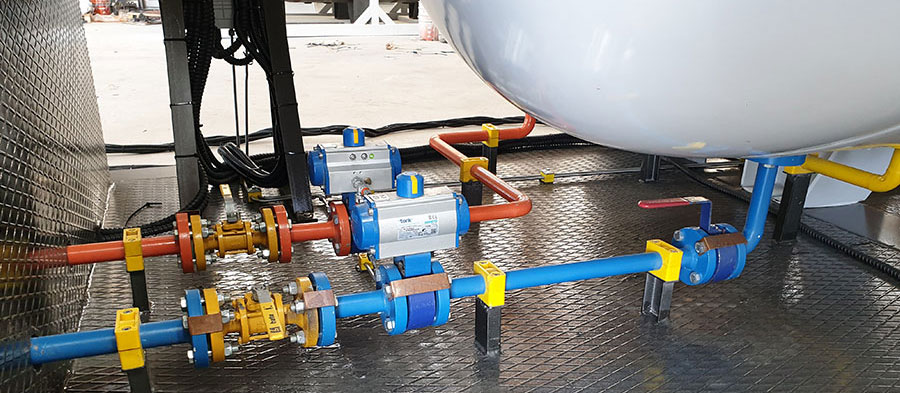

- The system provided with high safety shut down system by adding sensors around station ,these sensors connected to electronic panel

- In case of gas leakage from the system, the gas sensor will give the order to system to shut down by closing the Pneumatic valves and LPG pump that connected to this system

Skid with automation system:

TECHNICAL SPECIFICATIONS

Download catalogue| DESIGN PARAMETERS FOR SKID TANK (PRESSURE VESSEL) | |

|---|---|

| Design Code | AD 2000 MERKBALTTER, EN 12493 ,EN 13445 ,ASME CODE and other codes |

| Capacity | ( 5 - 100 m3 ) |

| Body Type | Horizontal, Cylindrical |

| Heads Type | Elliptical or Hemispherical , Heat treatment 600 C º |

| Material | SA 516 Gr 70 / EN-10028.3 ( P355NH-P355NL1) / EN-10028.2 ( P355GH-P265GH) |

| Design Temperature | (-20 C° / +70 C°) |

| Design Pressure | 17,1 - 18 BAR |

| Test Pressure | 26,25 - 27.5 BAR |

| Welding | SAW -Submerged Arc Welding |

| Piping | SCH 40, SCH80 seamless pipes |

| Tests | UT (Ultrasonic Test ) - X-Ray :RT ( RadiographicTest ) - BT ( Beta Test ), Hydrostatic Test |

| Paint | Sandblasting will be done firstly, 2 layers of epoxy base paint, then 2 layers of paint. |